Discover essential ADAS maintenance tips for safety sensors to ensure peak vehicle performance. Trust Auto Service Solutions for expert ADAS calibration and repair, and Auto Tech Services for top-notch collision repair. Prioritize regular system updates, sensor calibration, and comprehensive vehicle safety checks to keep your vehicle safe on the road.

ADAS Maintenance Tips For Safety Sensors

Modern driving relies heavily on advanced vehicle technologies to keep you safe. Regular maintenance for safety sensors plays a significant role in maintaining optimal performance.

Routine vehicle safety checks ensure all systems work harmoniously.

Sensor calibration is essential for enhancing features like lane departure warning and obstacle detection.

Timely system updates help prevent issues and boost reliability, especially with adaptive cruise control functions. Auto Service Solutions specializes in ADAS calibration and repair, guaranteeing that vehicles operate at peak efficiency.

For collision needs, Auto Tech Services is dedicated to ensuring your vehicle's safety features remain intact. Being aware of when to check sensors is important.

Signs of faulty sensors may include warning lights on the dashboard, indicating a need for immediate attention.

Understanding Sensor Calibration Importance

Accurate sensor functionality directly influences vehicle safety and overall performance. Sensor positioning affects how effectively safety systems respond to potential hazards.

Regular calibration is necessary to ensure the precision of technologies, including parking assistance and blind spot detection.

Properly functioning vehicle safety systems play a significant role in accident prevention.

Misalignment can lead to erroneous alerts or, worse, overlooked warnings. For instance, forward collision alert systems depend on calibrated ultrasonic technology to detect obstacles.

Consistent maintenance of these systems is important for maintaining high safety standards and boosting driver confidence on the road.

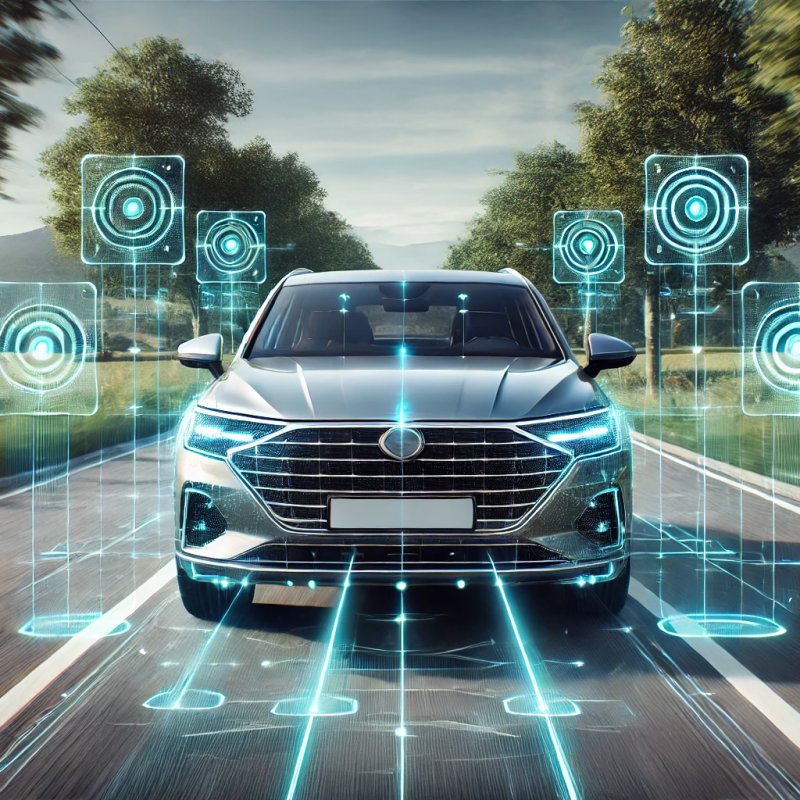

How Lane Departure Warning Works

Enhancing vehicle safety involves the implementation of innovative technologies. Cameras and sensors play a crucial role in accurately identifying lane markings.

When a vehicle unintentionally drifts from its lane, the system triggers alerts.

Visual checks, audible signals, or tactile vibrations instantly inform the driver.

This functionality prevents accidents related to driver inattention. Regular maintenance protocols help ensure the system operates effectively.

Failure to maintain these systems may result in reduced performance. Effective lane detection depends on the calibration and functionality of the implemented technologies.

Software upgrades may also be necessary to adapt to varying road conditions.

Vehicle Safety Technologies

- Cameras and sensors significantly improve lane detection accuracy.

- Alert systems reduce the risk of accidents caused by driver inattention.

- Regular maintenance is essential for optimal performance of safety systems.

- Software upgrades are important to keep pace with changing road conditions.

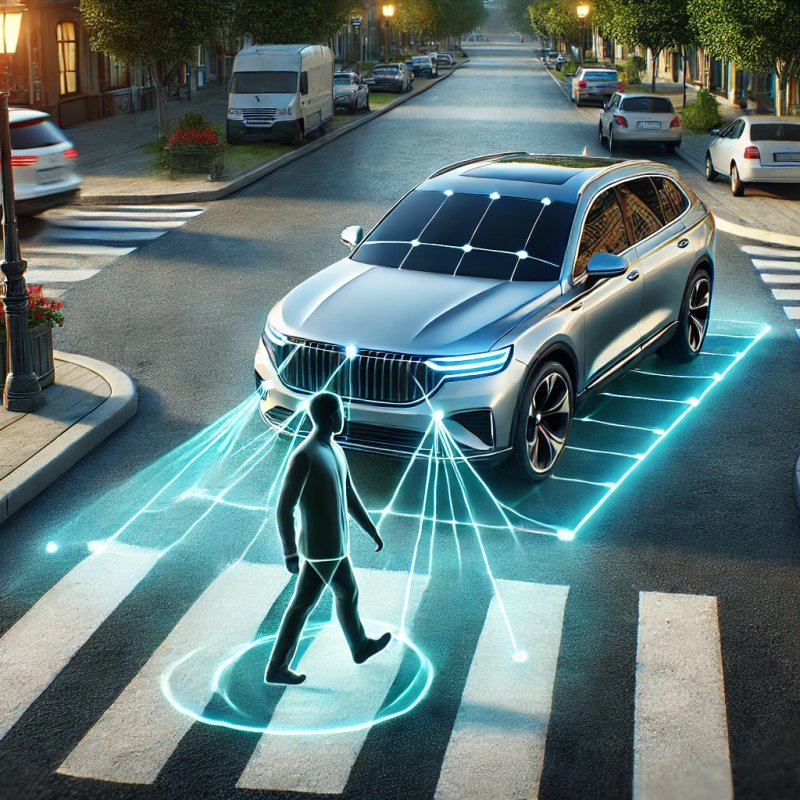

Tips For Effective Obstacle Detection

Achieving optimal awareness on the road mandates a comprehensive grasp of the technologies involved. Sensor technology is fundamental, as it significantly enhances detection accuracy.

Regular calibration of sensors must not be overlooked; performance evaluation directly depends on this practice.

System integration of various sensors can improve responsiveness.

Maintaining sensor cleanliness is vital; dirt and debris obstruct functionality. Conducting periodic system checks ensures safety assessments yield positive results, leading to heightened awareness.

Employing the right calibration tools can make a substantial difference in reliability. By following these recommendations, drivers can elevate their safety measures on the road.

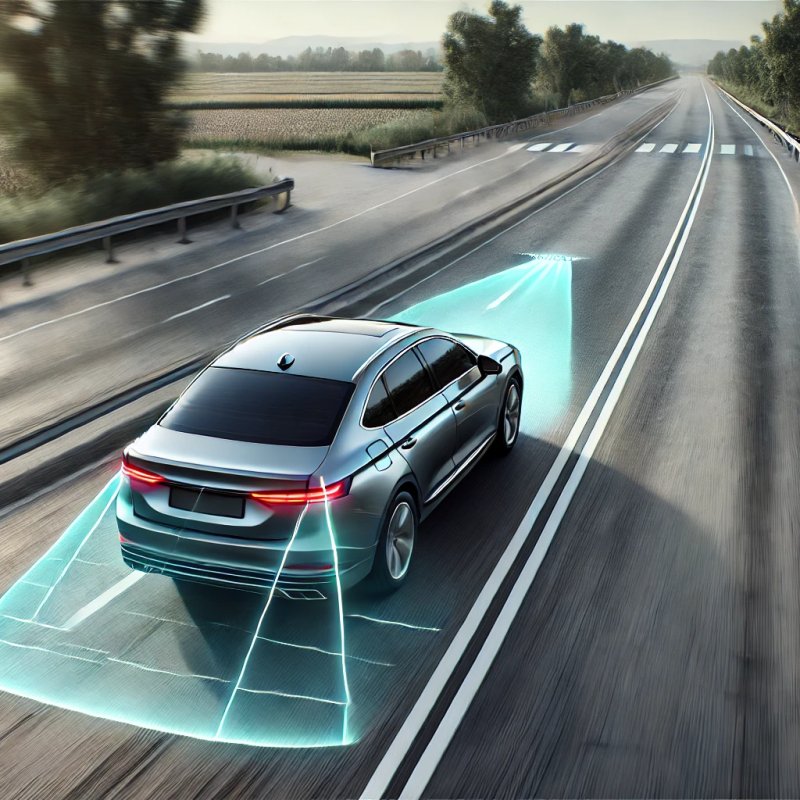

Ensuring Adaptive Cruise Control Reliability

Reliable systems in modern vehicles enhance safety and driving enjoyment. The effectiveness of adaptive cruise control is influenced significantly by sensor categories designed for various conditions.

Quality components are imperative for smooth operation, especially when faced with changing environmental factors.

Regular operational inspections play a vital role in identifying potential issues before they become problematic.

By prioritizing preventive care, the lifespan of vehicle electronics can be greatly increased. Keeping all sensor categories in optimal working order is essential for effective performance.

Routine assessments not only promote safe driving experiences but also enhance reliability. Incorporating troubleshooting techniques and timely updates ensures consistent performance.

Staying informed about system requirements is key to achieving a higher standard of safety and dependability.

| Key Component | Importance |

|---|---|

| Adaptive Cruise Control Sensors | Essential for maintaining speed and distance in varying conditions |

| Quality Components | Imperative for smooth operation and reliability |

| Regular Inspections | Vital for identifying potential issues early |

| Preventive Care | Increases the lifespan of vehicle electronics |

Radar Alignment Techniques For Safety

Accurate calibration not only enhances vehicle functionality but also plays a pivotal role in safety outcomes. Driver assistance systems depend heavily on refined radar alignment to ensure reliable operation.

Precision in measurements leads to correct sensor alignment, which is fundamental for adhering to stringent safety standards.

Implementing structured inspection strategies allows for the timely identification of misalignment issues, preempting serious risks.

Regular maintenance and service intervals help keep performance at its peak, thereby boosting dependability. Continuous tech updates are necessary to address evolving radar demands and optimize function.

Environmental influences, including varying weather conditions, also necessitate adaptive adjustments for consistent performance. Enforcing these radar alignment methods significantly promotes vehicle safety while minimizing accident potential.

Importance Of Regular Camera Maintenance

Proper upkeep of your camera significantly impacts overall functionality and image quality. Achieving system efficiency relies on consistent care, which plays a pivotal role in photography.

Regular cleaning eliminates dust and debris, ensuring every shot captures clarity.

Important components, including sensors, greatly benefit from these maintenance routines.

Routine firmware updates enhance sensor precision, allowing cameras to utilize the latest innovations and features. Prioritizing these essential tasks helps avoid expensive repairs while extending the lifespan of your equipment.

Familiarity with these practices is important for any photographer's success.

- Enhances Performance: Consistent maintenance enhances your device's performance significantly, ensuring clear, high-quality images and reliable functionality.

- Prevents Costly Repairs: Investing time in maintenance can effectively prevent future costly repairs, as neglect can lead to larger issues over time.

Main Discussion Points:

- Routine Cleaning: Thorough cleaning of components such as lenses and sensors prevents dust accumulation, greatly contributing to optimal image clarity and quality.

- Firmware Updates: Keeping the firmware updated is instrumental in maintaining compatibility with accessories and leveraging smart technology features.

Critical Questions:

- What are common maintenance tasks that can be easily performed at home?

- How often should professional maintenance services be considered for your camera?

Camera Maintenance

- Regular cleaning can improve image quality by up to 30%, reducing the impact of dust and smudges on lenses and sensors.

- Firmware updates can introduce new features and improve performance, with some updates leading to a 20% increase in processing speed.

- Neglecting maintenance can result in repair costs that exceed 50% of the camera's original value over time.

- Professional maintenance services should be considered at least once a year to ensure optimal performance and longevity of the camera.

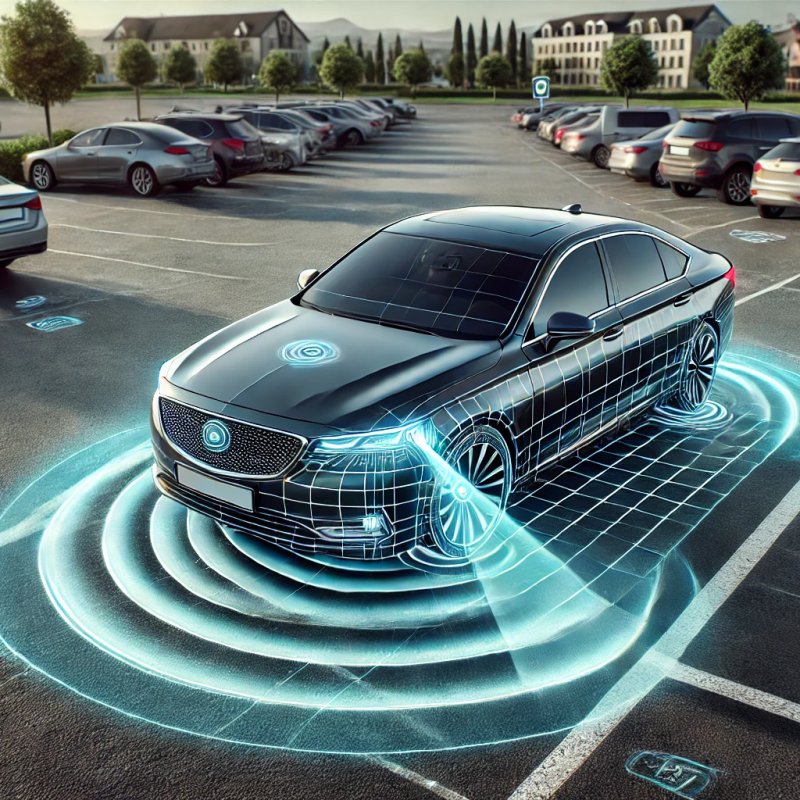

Best Practices For Sensor Positioning

Achieving optimal performance in vehicles hinges on smart sensor deployment. Proper positioning of the electrical components significantly enhances accuracy and reliability.

Attention to road conditions and vehicle architecture is necessary for effective functionality.

Strategic arrangements yield precise readings, essential for advanced driver systems.

Routine testing and maintenance ensure the dependability of these components over time. Calibration processes reinforce measurement accuracy, facilitating vehicle enhancements that bolster safety.

By implementing recommended practices, continuous performance monitoring is achievable, ensuring robust operation across diverse driving scenarios. This methodology bridges the understanding between maintenance and the assessment of overall vehicle safety systems.

Functional Assessment Of Vehicle Safety Systems

Comprehensive evaluations of safety components are necessary to ensure their effectiveness in maintaining vehicle integrity. Performance indicators are significantly enhanced through consistent monitoring, which prevents unforeseen issues from arising.

Implementing robust maintenance strategies is key to preserving the functionality of these systems.

Sensor calibration is imperative for achieving reliability, influencing both operational efficiency and safety.

Employing rigorous inspection methodologies can uncover potential failures early, keeping drivers protected on the road. Service suggestions issued by manufacturers provide essential guidance for optimal system performance.

Technology adjustments should be promptly addressed, aligning systems with current safety standards to bolster vehicular safety systems.

Vehicle Safety Components

- Regular evaluations of safety components can reduce the likelihood of vehicle accidents by identifying potential failures early.

- Consistent monitoring of performance indicators can lead to a 30% increase in the reliability of vehicle systems.

- Robust maintenance strategies can extend the lifespan of safety components by up to 50%.

- Sensor calibration can improve operational efficiency by ensuring that systems respond accurately to real-time conditions.

Related Posts

Contact

We’re here to help!

Call to schedule a service or ask about our offerings.